Galvanized C-Beam

Place of Origin: Shandong, China

Grade: Q235b, Q355b, SS304, SS316, etc.

Technology: Hot Rolling

Thickness: standard and customized, 2.0mm, 2.5mm, 2.75mm, 3.0mm and customized

Application: ships, automobiles, bridges, construction, machinery

Length: standard and customized

Standard: ASTM, GB ASTM ANSI JIS

Flange width: standard and customized

Width: standard and customized

Coil thickness: standard and customized

Brand Name: Blanket

Model: DKCM-0101

Tolerance: ±5%

Processing services: bending, welding, punching, cutting

Product name: H-beam

Technology: Hot Rolling

Size: standard size and customized size

Shape: C profile, U profile, Z profile, L profile, H profile

Hot dip standard: GB/T 13912-2016

Surface: plain, black and surface treatment

Sample: free sample

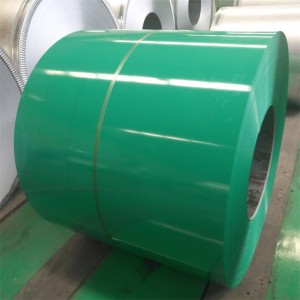

Galvanized C-shaped steel refers to a new type of steel that is made of high-strength steel, cold-formed and roll-formed, with uniform wall thickness, excellent cross-section properties, and high strength. Compared with traditional hot rolling, the same strength can save 30% of materials.

Galvanized C-shaped steel has the advantages of adjustable size and high compressive strength. The section steel formed by cold bending, although its cross-section size is light and handy, is in line with the stress characteristics of roof purlins, so that the mechanical performance of the steel can be utilized. A variety of accessories can be connected into different combinations. The appearance is beautiful. The use of profiled steel purlins can reduce the weight of building roofs and reduce the amount of steel used in engineering. Therefore, it is called economical and efficient steel. It is an alternative to traditional steel such as angle steel, channel steel, and steel pipe. New building materials for purlins

1. Durable and durable: In urban areas or offshore areas, the standard hot-dip galvanized anti-corrosion layer can be used for 20 years; in the suburbs, it can be used for more than 50 years.

2. Comprehensive protection: every part can be plated with zinc and is fully protected.

3. The coating has strong toughness: it can withstand mechanical damage during transportation and use.

4. Good reliability.

5. Time-saving and labor-saving: the galvanizing process is faster than other coating construction methods, and it can avoid the time required for painting on the construction site after installation.

6. Low cost: It is said that galvanizing is more expensive than spray paint, but in the long run, the cost of galvanizing is low, because galvanizing is durable and long-lasting.

Galvanized C-shaped steel is widely used in the purlins and wall beams of steel structure buildings, and can also be assembled into lightweight roof trusses, brackets and other building components. In addition, it can also be used for columns, beams and arms in mechanical light industry manufacturing.

Galvanized C-shaped steel is automatically processed and formed by a C-shaped steel forming machine. The C-shaped steel forming machine can automatically complete the C-shaped steel forming process according to the given C-shaped steel size.

Unwinding①——Leveling②——Forming③——Shaping④——Straightening⑤——Length measurement⑥——Punching and bracing round hole⑦——Punching oval connecting hole⑧——forming and cutting ⑨

According to the different smelting quality of steel, section steel is divided into ordinary section steel and high-quality section steel. Ordinary section steel is divided into large section steel, medium section steel and small section steel according to the current metal product catalog. Ordinary steel can be divided into I-beam, channel steel, angle steel, round steel, etc. according to its cross-sectional shape.

Large section steel: In large section steel, I-beam, channel steel, angle steel, and flat steel are all hot-rolled. In addition to hot-rolled round steel, square steel, and hexagonal steel, there are also forging and cold-drawn.

I-beam, channel steel, and angle steel are widely used in industrial buildings and metal structures, such as factory buildings, bridges, ships, agricultural machinery and vehicle manufacturing, power transmission towers, and transportation machinery, and they are often used in conjunction. Flat steel is used in construction sites as bridges, house trusses, fences, power transmission ships, vehicles, etc. Round steel and square steel are used as various mechanical parts, agricultural machinery parts, tools, etc.

Medium-sized steel: Medium-sized steel, groove, corner, round, flat steel, similar to large-sized steel.

Small section steel: Small section steel has medium angle, round, square, flat steel, processing and use are similar to large section steel, small diameter round steel is often used as building reinforcement

|

Product name |

H beam |

|

Standard |

Astm, bs, gb, jis, etc. |

|

Grade |

Ss400, st37-2, a36, s235jrg1, q235, q345, etc. |

|

Specification |

100*100*6*8mm~900*300*18*34mm |

|

Thickness |

6-35mm |

|

Length |

6m, 9m, 12m or customized |

|

Surface treatment |

Hot dip galvanized/black/painted |

|

Zinc coating |

30-90um |

|

Package |

Bundling |

|

Delivery time |

10-20 days |

|

Payment terms |

L/c, t/t or western union |