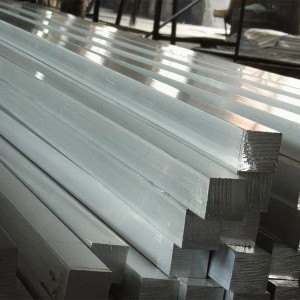

Ordinary Track Steel

Light weight, high strength, flame retardant, anti-explosive, anti-static, high temperature resistance, acid and alkali resistance, etc. can be produced according to customer requirements to meet various special requirements.

Steel track

Relatively speaking, the use range and life span of steel track and the choice of working conditions are wider. It is composed of steel tracks, crawler wheels, guide wheels, supporting wheels, chassis and two traveling reducers (traveling reducers are composed of motors, gear boxes, brakes, and valve bodies). Generally, for example, the drilling rig is arranged on the chassis as a whole, and the walking speed of the crawler chassis is adjusted by the control handle, so that the whole machine can realize convenient movement, turning, climbing, walking, etc.

Tracked chassis

Rubber shoes

Rubber crawler chassis are mostly suitable for small light industry and small construction machinery industry. Light industry is generally agricultural machinery within one to four tons. The construction machinery industry is mostly used in the small drilling industry.

The choice of operating environment is roughly as follows:

(1) The operating temperature of rubber tracks is generally between -25 and +55'C.

(2) Chemicals, oil, and salt in sea water will accelerate the aging of the crawler. Clean the crawler after use in such an environment.

(3) The road surface with sharp protrusions (such as steel bars, stones, etc.) will cause trauma to the rubber track.

(4) The curbstone, rut or uneven road surface of the road will cause cracks in the pattern on the grounding side of the crawler edge. Such cracks can continue to be used if the steel cord is not damaged.

(5) Gravel and gravel roads will cause early wear of the rubber surface in contact with the load-bearing wheels, forming small cracks. In severe cases, water invades, causing the core iron to fall off and the steel wire to break.