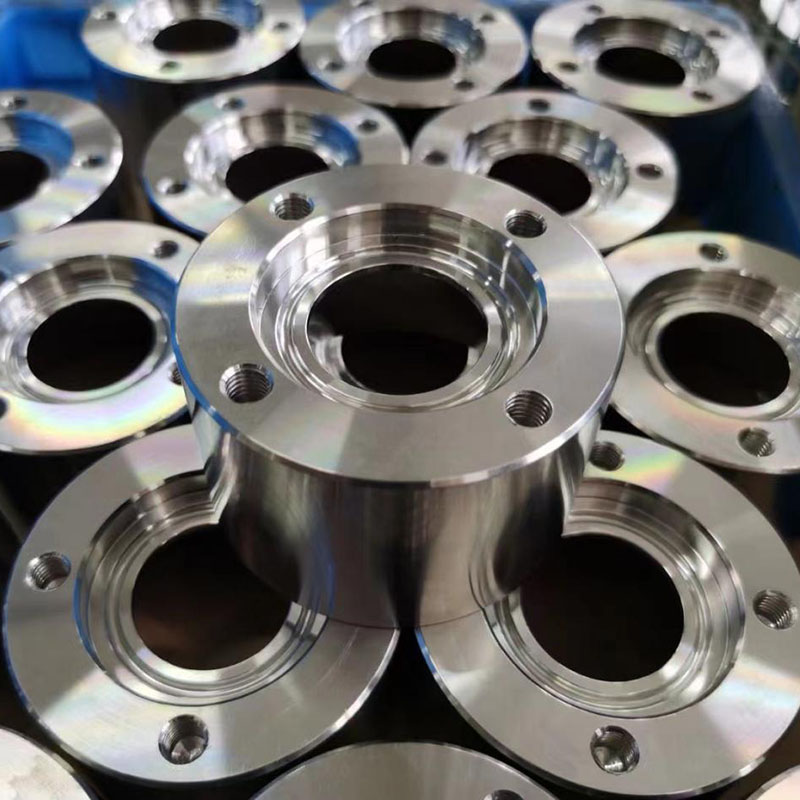

Pipe Fittings Stainless Steel Rf Blind Welding Neck Flange

Carbon Steel: ASTM A105, 20#, Q235, 16Mn; ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2; ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless Steel: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8.

Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/III.

WCB (carbon steel), LCB (low temperature carbon steel), LC3 (3.5% nickel steel), WC5 (1.25% chromium 0.5% molybdenum steel), WC9 (2.25% chromium), C5 (5% chromium 0.5% molybdenum), C12 (9% chromium 1% molybdenum), CA6NM (4 (12% chromium steel), CA15 (4) (12% chromium), CF8M (316 stainless steel), CF8M (316 stainless steel) CF8C (347 stainless steel), CF8 (304 stainless steel), CF3 (304L stainless steel), CF3M (316L stainless steel), CN7M (alloy steel), M35-1 (Monel), N7M (Hastelloy B), CW6M (Hastelloy C), CY40 (Inconel), etc.

Plate flat welding steel pipe flange plate

1. According to the chemical industry (HG) industry standards: integral flange (IF), threaded flange (Th), plate flat welding flange (PL), necked butt welding flange (WN), necked flat welding flange (SO), socket welding flange (SW), butt welding ring loose flange (PJ/SE), flat welding ring loose flange (PJ/RJ), lined flange cover (BL (S)), flange cover (BL)

2. according to the petrochemical (SH) industry standards: threaded flange (PT), butt welding flange (WN), flat welding flange (SO), socket welding flange (SW), loose flange (LJ), flange cover (not table note).

3. according to the machinery (JB) industry standards: the whole flange, butt welding flange, plate flat welding flange, butt welding ring plate loose flange, flat welding ring plate loose flange, flanged ring plate loose flange, flange cover.

4. according to the national (GB) standard: the whole flange, threaded flange, butt welding flange, necked flat welding flange, necked socket welding flange, butt welding ring necked loose set flange, plate type flat welding flange, butt welding ring plate type loose set flange, flat welding ring plate type loose set flange, flanged ring plate type loose set flange, flange cover.

Flange widely used in water conservancy, electric power, power station, pipeline fittings, industry, pressure vessels and other boiler pressure vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, food and other industries. HVAC Electric power Building water supply Pressure vessel fittings, pressure pipe fittings. Applicable to fire, gas, hot and cold water, air conditioning, air pressure pipe, oil pipe, instrumentation, hydraulic pipe and other industrial and civil pipe thread locking seal, etc.

Reducing flange; stainless steel flange; pressure vessel flange; flat welding flange; necked butt welding (WN) socket welding flange (SW); threaded flange (TH) loose-fitting flange

National standard: GB/T9112-2010 (GB9113-1-2010~GB9123-4-2010)

Ministry of Chemical Industry standards: HG5010-52~HG5028-58, HGJ44-91~HGJ65-91, HG20592-2009 series, HG20615-2009 series

Ministry of Machinery standards: JB81-59 ~ JB86-59, JB/T79-94 ~ JB/T86-94, JB/T74-1994

Pressure vessel standards: JB1157-82 ~ JB1160-82, NB/T47020-2012 ~ NB/T47027-2012, B16.47A/B B16.39 B16.

| Item | Flange types | Size range (mm) | Tolerance (mm) |

| Flange thickness C | All types of double-sided processing | C≤18 | +20 |

| 18<C≤50 | +30 | ||

| C>50 | +40 | ||

| Flange height H | Flat welding, butt welding, loose sleeve, socket welding flange | ≤DN250 | ±1.5 |

| DN300~DN600 | ±3.0 | ||

| Flange outer diameter D | All types | ≤DN150 | ±1.5 |

| DN200~DN500 | ±3.0 | ||

| Seal surface height F | All types | All sizes | ±0.50 |

| Bolt hole center circle diameter K | All types | M10~M24 | ±1.0 |

| M27~M33 | ±1.25 | ||

| M36~M52 | ±1.5 | ||

| Bolt hole diameter L | All types | ≥DN10 | ±0.5 |

| Coaxial tolerance of the center circle of the bolt hole and the machined sealing surface | All types | ≤DN65 | Φ1.0 |

| DN80~DN150 | Φ2.0 | ||

| DN200~DN500 | Φ4.0 |