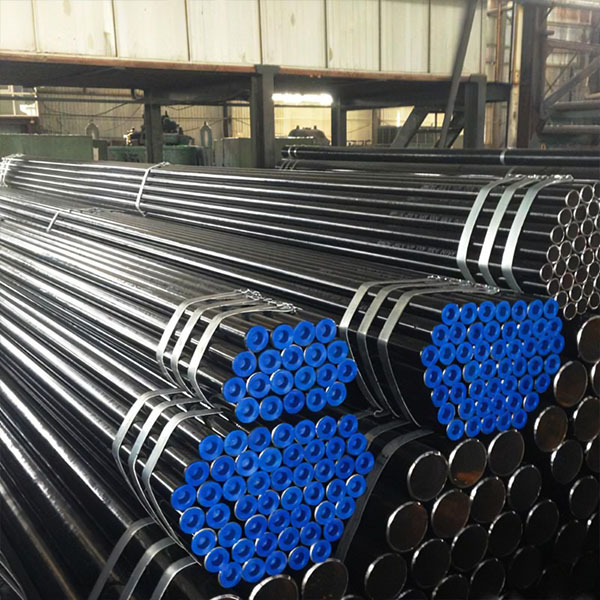

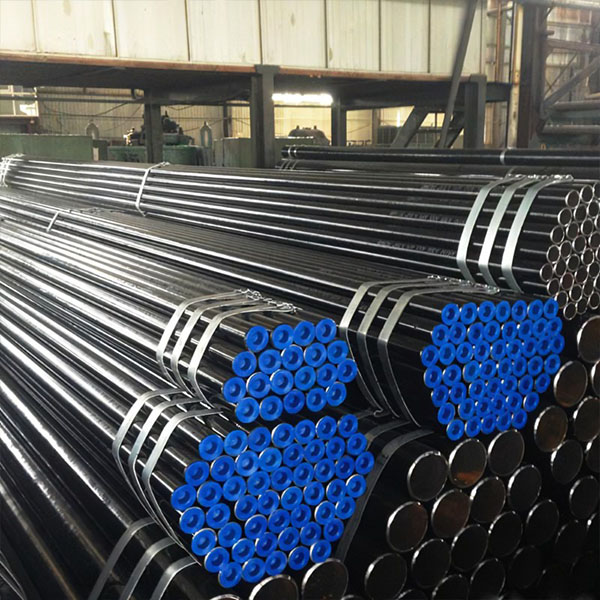

P91 Solid Alloy Tube

P91 alloy pipe according to GB/T8162-87

4.1. Specifications: The outer diameter of the hot-rolled tube is 32~630mm. The wall thickness is 2.5~75mm. The outer diameter of cold rolled (cold drawn) pipe is 5~200mm. The wall thickness is 2.5-12mm.

4.2. Appearance quality: the inner and outer surfaces of the steel pipe must not have cracks, folds, rolls, delamination, hair lines and scarring defects. These defects should be completely removed, and the wall thickness and outer diameter must not exceed the negative deviation after removal.

Manufacturing method

According to different production methods, it can be divided into hot-rolled tubes, cold-rolled tubes, cold-drawn tubes, extruded tubes, etc.

1.1. Hot rolled P91 alloy tubes are generally produced on automatic tube rolling mills. The solid tube is inspected and cleaned of surface defects, cut to the required length, centered on the perforated end of the tube, and then sent to the heating furnace to be heated and pierced on the piercing machine. When the perforation continuously rotates and advances at the same time, under the action of the roller and the plug, a cavity is gradually formed inside the tube blank, which is called a capillary tube. And then sent to the automatic rolling mill to continue rolling. Finally, the whole wall thickness is uniformed by the equalizing machine, and the diameter is sizing by the sizing machine to meet the specification requirements. It is a more advanced method to produce hot-rolled P91 alloy pipes using continuous pipe rolling mills.

1.2. If you want to obtain seamless pipes with smaller size and better quality, cold rolling, cold drawing, or a combination of the two methods must be used. Cold rolling is usually carried out on a two-high rolling mill. The steel pipe is rolled in an annular pass formed by a variable cross-section circular hole groove and a stationary tapered plug. Cold drawing is usually carried out on a single-chain or double-chain cold drawing machine of 0.5 to 100T.

1.3. The extrusion method is to put the heated tube blank in a closed extrusion cylinder, and the perforated rod and the extrusion rod move together to extrude the extruded part from the smaller die hole. This method can produce steel pipes with smaller diameters.

2.1. P91 alloy tube has a wide range of uses. The general-purpose P91 alloy pipe is rolled from ordinary carbon structural steel, low-alloy structural steel or alloy structural steel, and has the largest output. It is mainly used as pipelines or structural parts for conveying fluids.

2.2. According to different purposes, it is divided into three types of supply: a. According to chemical composition and mechanical properties; b. According to mechanical properties; c. According to hydraulic test. Steel pipes supplied according to categories a and b, if used to withstand liquid pressure, shall also be subjected to a hydraulic test.

2.3. P91 alloy pipes for special purposes include P91 alloy pipes for boilers, P91 alloy pipes for geology and seamless pipes for petroleum.

The main alloying elements of alloy pipes are silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, copper, boron, rare earth, etc.Alloy steel pipes contain iron, carbon and a small amount of indispensable In addition to avoiding silicon, manganese, phosphorus, and sulfur, it also contains a certain amount of alloying elements.The alloying elements in steel include silicon, manganese, molybdenum, nickel, sulphur, vanadium, titanium, niobium, boron, lead, rare earths, etc. One or more types of steel are called alloy steels. The alloy steel systems vary with their respective resource conditions, production and use conditions. In the past, nickel and steel systems have been developed in foreign countries. China has found that silicon, manganese, Vanadium, titanium, niobium, boron, lead, and rare earth alloy steel system alloy steel accounts for about ten percent of the total output of steel. Generally, alloy steel pipes can be divided into 8 major types according to their uses. Types, they are: alloy structural steel pipes, spring steel pipes, bearing steel pipes, alloy tool steel pipes, high-speed tool steel pipes, stainless steel pipes, heat-resistant non-skin steel pipes, electrical silicon steel pipes PC/ABS have good formability and can be processed for large cars Components, such as automobile fenders, have a high cost performance. Alloy steel pipes are made of ordinary carbon steel by adding an appropriate amount of one or more alloying elements to the classification of iron-carbon alloy steel pipes: steel pipes are divided into P91 alloy pipes and welding Steel pipes and so on.