Cold-Formed Steel

Cold-formed steel refers to a variety of complex cross-section profiles made from hot-rolled or cold-rolled strip steel under pressure processing at room temperature. Also known as thin-walled steel, it is a kind of light building structural steel. Cold-formed steel has been produced for more than 100 years, and it was originally produced on a single machine with a bending press. In 1910, the United States first built the first continuous roll forming unit. After 1960, cold-formed steel has developed rapidly. In 1989, its annual world output reached 8 million tons, with more than 10,000 varieties and specifications. The output of cold-formed steel in industrial developed countries accounts for about 5% of the total output of steel. China built its first cold-formed steel production unit in Shanghai in 1958. By the end of the 1980s, there were more than 30 forming units, producing nearly 100 varieties and an annual output of more than 200,000 tons of cold-formed steel.

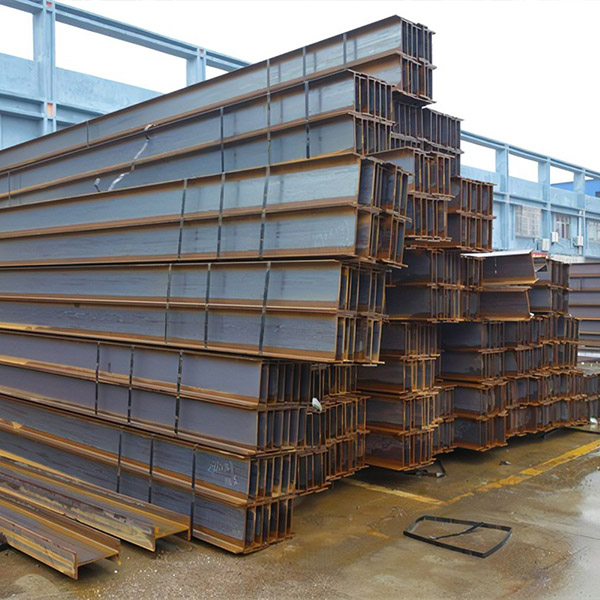

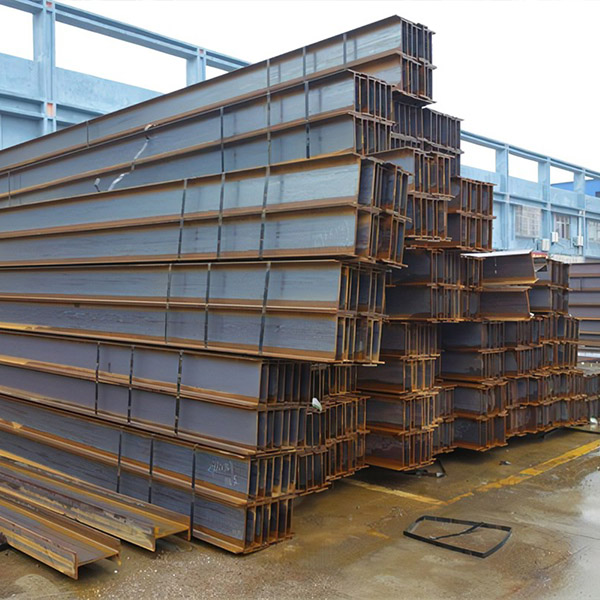

Cold-formed steel is a kind of economical cross-section, light-weight thin-walled steel, also called steel refrigerated steel or cold-formed steel. Cold-formed steel is the main material for making light steel structures. It has various ultra-thin, reasonable and complex cross-sections that cannot be produced by hot rolling. Compared with hot-rolled steel, in the case of the same cross-sectional area, the radius of gyration can be increased by 50% to 60%, and the moment of inertia of the section can be increased by 0.5 to 3.0 times, so the material strength can be used more reasonably; (That is, the steel structure made of traditional I-beam, channel steel, angle steel and steel plate) can save about 30% to 50% of steel. In some cases, the amount of steel used in cold-formed steel structures is equivalent to that of reinforced concrete structures under the same conditions, which is an economical section steel.

Cold-formed steel has a wide range of uses, and is generally used to make structural parts and auxiliary parts in production departments such as construction, railway vehicles, automobiles, and ships.

There are many types of cold-formed steel, divided into open, semi-closed and closed cross-sectional shapes. The main products are cold-formed channel steel, angle steel, Z-shaped steel, cold-formed corrugated steel plate, square pipe, rectangular pipe, electric welded special-shaped steel pipe, rolling shutter door Wait. Cold-formed steel generally produced has a thickness of 6mm or less and a width of 500mm or less. Commonly used specifications in our country are equilateral angle steel (leg length 25~75mm), inner curling angle steel (leg length 40~75mm), channel steel (high 25~250mm), inner curling channel steel (high 60~250mm), curling Z-shaped steel (100~180mm high) and more than 400 specifications and varieties. Products are widely used in mining, construction, agricultural machinery, transportation, bridges, petrochemical, light industry, electronics and other industries.

Cold-formed steel is the main material for making light steel structures, and it is made of cold-formed steel plates or steel strips. Its wall thickness can not only be made very thin, but also greatly simplifies the production process and improves production efficiency. It can produce various profiles and cold-formed steels of different materials with uniform wall thickness, which are difficult to produce by general hot rolling methods, but with complex cross-sectional shapes. In addition to being used in various building structures, cold-formed steel is also widely used in vehicle manufacturing and agricultural machinery manufacturing. There are many varieties of cold-formed steel, which are divided into open, semi-closed and closed according to the section. According to the shape, there are cold-formed channel steel, angle steel, Z-shaped steel, square tube, rectangular tube, special-shaped tube, rolling shutter door, etc. The latest standard 6B/T 6725-2008 has added the yield strength classification of cold-formed steel products, added fine-grained steel, and increased the specific assessment indicators for the mechanical properties of the product.