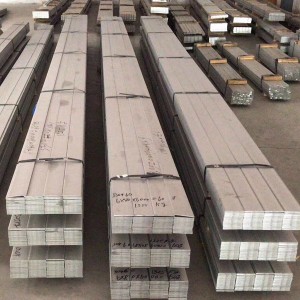

Spring Flat Steel

1. Making flat steel with converter mainly uses molten iron as raw material. There are few harmful elements in molten iron, and the quality of flat steel produced is guaranteed.

2. Due to high yield and low power consumption, the cost per ton is lower than that of electric furnace.

3. Molten steel is directly cast into billet, which omits the billet opening process and reduces the cost.

4. The continuous casting billet has high sizing rate, which can ensure the sizing rate of flat steel and meet the needs of users.

Ferrous metals, steel and non-ferrous metals

Before introducing the classification of steel, briefly introduce the basic concepts of ferrous metals, steel and non-ferrous metals.

1. Ferrous metals refer to iron and iron alloys. Such as steel, pig iron, ferroalloy, cast iron, etc. Steel and pig iron are alloys based on iron and with carbon as the main added element, which are collectively referred to as iron carbon alloys.

Pig iron is the product of smelting iron ore into blast furnace, which is mainly used for steelmaking and casting. Cast pig iron is melted in an iron melting furnace to obtain cast iron (liquid). The liquid cast iron is cast into a casting. This kind of cast iron is called cast iron. Ferroalloy is an alloy composed of iron and silicon, manganese, chromium, titanium and other elements. Ferroalloy is one of the raw materials for steelmaking. It is used as deoxidizer and alloy element additive for steel during steelmaking.

2. Steel is obtained by melting pig iron for steelmaking in a steelmaking furnace according to a certain process.

3. Nonferrous metals, also known as non-ferrous metals, refer to metals and alloys other than ferrous metals, such as copper, tin, lead, zinc, aluminum, brass, bronze, aluminum alloy and bearing alloy. In addition, chromium, nickel, manganese, molybdenum, cobalt, vanadium, tungsten and titanium are also used in industry. These metals are mainly used as alloy additives to improve the performance of metals. Tungsten, titanium and molybdenum are mostly used to produce cemented carbide for cutting tools. These non-ferrous metals are called industrial metals. In addition, there are precious metals: platinum, gold, silver and rare metals, including radioactive uranium and radium.

Classification by use

(1) Steel for construction and Engineering: ordinary carbon structural steel; Low alloy structural steel; Steel reinforcement.

(2) Structural steel

Steel for machinery manufacturing: Quenched and tempered structural steel; Surface hardening structural steel: including carburized steel, ammoniated steel and surface quenching steel; Easy to cut structural steel; Steel for cold plastic forming: including steel for cold stamping and steel for cold heading.

(1) Special performance steel: Stainless and acid resistant steel; Heat resistant steel: including oxidation resistant steel, heat strength steel and air valve steel; Electric heating alloy steel; Wear resistant steel; Low temperature steel; Electrical steel.

(2) Professional steel: such as bridge steel, ship steel, boiler steel, pressure vessel steel, agricultural machinery steel, etc.