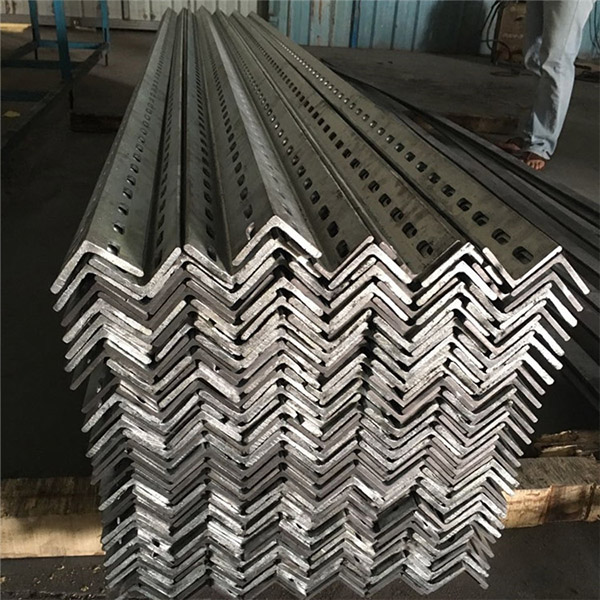

Hot-Dip Galvanized Angle Steel

Standard: GB

Grade: SS400-SS540 series

made in China

Model: 50*50*5 etc.

Type: Isometric

Application: Steel structure

Tolerance: ±1%

Processing services: bending, welding, punching, uncoiling, cutting

Alloyed or not: Non-alloyed

Invoice: According to actual weight

Delivery time: 8-14 days

Product Name: Angle Steel

Technology: Hot rolled angle steel

Shape: equiangular bar

Keywords: Angle iron size! price

According to the process classification, it can be divided into hot-dip galvanized angle steel and cold-dip galvanized angle steel. Hot-dip galvanized angle steel is common in the market. Cold-galvanized angle steel generally needs to be cold-plated according to user needs. According to the side length, it can be divided into galvanized equilateral angle steel and galvanized unequal angle steel.

1. Low processing cost: the cost of hot-dip galvanizing and rust prevention is lower than that of other paint coatings;

2. Durable and durable: Hot-dip galvanized angle steel has the characteristics of surface gloss, uniform zinc layer, no leakage plating, no dripping, strong adhesion, and strong corrosion resistance. In the suburban environment, the standard hot-dip galvanizing anti-rust thickness can be maintained Over 50 years without repairing; in urban areas or offshore areas, the standard hot-dip galvanized anti-corrosion layer can be maintained for 20 years without repairing;

3. Good reliability: The galvanized layer and the steel are metallurgically bonded and become a part of the steel surface, so the durability of the coating is more reliable;

4. The coating has strong toughness: the zinc coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use;

5. Comprehensive protection: every part of the plated parts can be plated with zinc, even in recesses, sharp corners and hidden places can be fully protected;

6. Time-saving and labor-saving: the galvanizing process is faster than other coating construction methods, and it can avoid the time required for painting on the construction site after installation.

Galvanized angle steel is widely used in power towers, communication towers, curtain wall materials, shelf construction, railways, highway protection, street light poles, marine components, building steel structural components, substation ancillary facilities, light industry, etc.

|

Specifications (side length * thickness) mm |

Mass (kg/m) |

Specifications (side length * thickness) mm |

Mass (kg/m) |

|

20*3 |

0.89 |

80*5 |

6.21 |

|

20*4 |

1.15 |

80*6 |

7.38 |

|

25*3 |

1.12 |

80*7 |

8.53 |

|

25*4 |

1.46 |

80*8 |

9.66 |

|

30*3 |

1.37 |

80*10 |

11.87 |

|

30*4 |

1.79 |

90*6 |

8.35 |

|

36*3 |

1.66 |

90*7 |

9.66 |

|

36*4 |

2.16 |

90*8 |

10.95 |

|

36*5 |

2.65 |

90*10 |

13.48 |

|

40*3 |

1.85 |

90*12 |

15.94 |

|

40*4 |

2.42 |

100*6 |

9.37 |

|

40*5 |

2.98 |

100*7 |

10.83 |

|

45*3 |

2.09 |

100*8 |

12.28 |

|

45*4 |

2.74 |

100*10 |

15.12 |

|

45*5 |

3.37 |

100*12 |

17.9 |

|

45*6 |

3.99 |

100*14 |

20.61 |

|

50*3 |

2.33 |

100*16 |

23.26 |

|

50*4 |

3.06 |

110*7 |

11.93 |

|

50*5 |

3.77 |

110*8 |

13.53 |

|

50*6 |

4.46 |

110*10 |

16.69 |

|

56*3 |

2.62 |

110*12 |

19.78 |

|

56*4 |

3.45 |

110*14 |

22.81 |

|

56*5 |

4.25 |

125*8 |

15.5 |

|

56*8 |

6.57 |

125*10 |

19.13 |

|

63*4 |

3.91 |

125*12 |

22.7 |

|

63*5 |

4.82 |

125*14 |

26.19 |

|

63*6 |

5.72 |

140*10 |

21.49 |

|

63*8 |

7.47 |

140*12 |

25.52 |

|

63*10 |

9.15 |

140*14 |

29.49 |

|

70*4 |

4.37 |

140*16 |

33.39 |

|

70*5 |

5.4 |

160*10 |

24.73 |

|

70*6 |

6.41 |

160*12 |

29.39 |