Leading Manufacturer for Gi Plate - Bright Precision Chilled Coil – JINBAICHENG

Leading Manufacturer for Gi Plate - Bright Precision Chilled Coil – JINBAICHENG Detail:

Product Introduction

The coil and the flat plate are almost a cut package, and the chilled coil is obtained by pickling and cold rolling of the hot-rolled coil. It can be said to be a kind of cold rolled coil. Cold-rolled coil (annealed): Hot-rolled coil is obtained by pickling, cold rolling, bell annealing, flattening and (finishing).

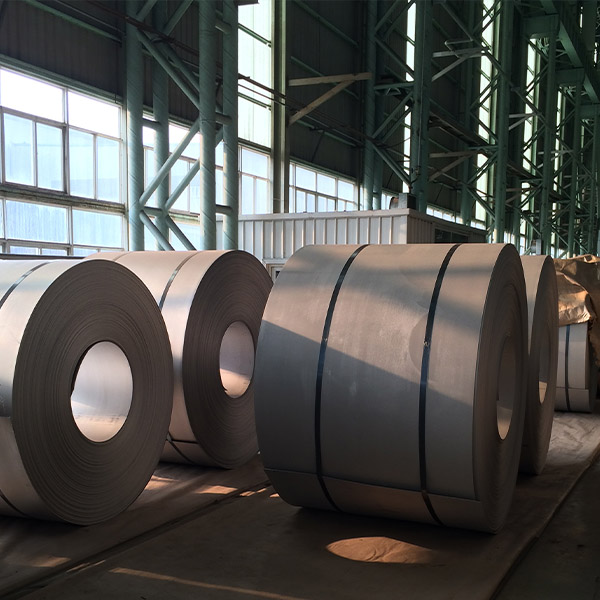

Product Display

The difference

There are three main differences between the two:

1. In appearance, the cold-hard coiled plate is a little blackish.

2. The surface quality, structure, and dimensional accuracy of cold-rolled sheets are better than chilled coils.

3. In terms of performance, because the chilled coils directly obtained by the cold rolling process of hot-rolled coils undergo work hardening during cold rolling, the yield strength is increased, and some internal stresses remain, and the external performance is relatively “hard”. Called chilled coil.

And cold-rolled coil (annealed state): It is obtained by bell-type annealing of the chilled coil before coiling. After annealing, the work hardening phenomenon and internal stress are eliminated (greatly reduced), that is, the yield strength is reduced close to the cold Before rolling.

Therefore, the yield strength: chilled coils are greater than cold-rolled coils (annealed), making cold-rolled coils (annealed) more conducive to stamping and forming.

Most steel is sold in coil form. After the enterprise purchases the coil, it has to go through the uncoiling process before processing, which is generally used in the automobile industry. Of course, there are also many automotive industries outsourcing the uncoiling process, and the factory directly uses the uncoiling sheet

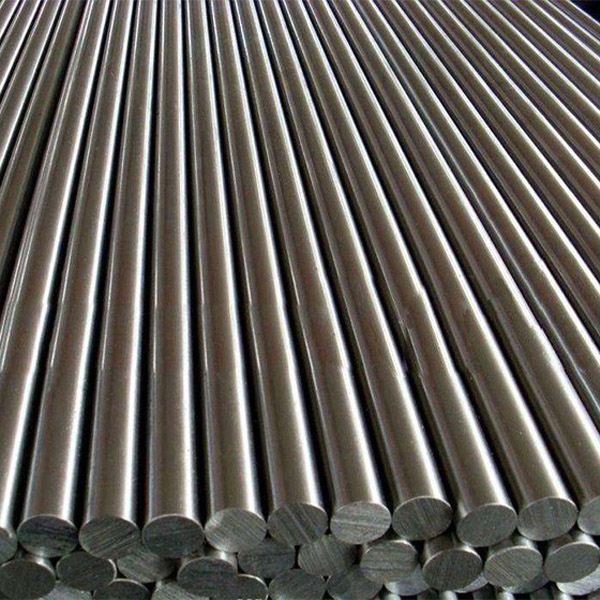

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Leading Manufacturer for Gi Plate - Bright Precision Chilled Coil – JINBAICHENG , The product will supply to all over the world, such as: Detroit, Iran, Bahamas, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!